|

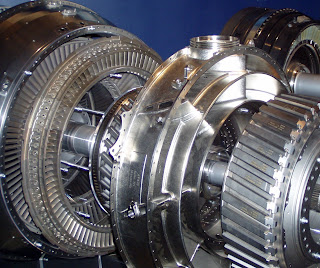

Specialized transmitter for monitoring moisture,

hydrogen, and temperature levels in electrical

transformers. (Vaisala) |

Electrical transformers are an intricate part of the power transmission and distribution system. Many transformers are insulated with mineral oil that also facilitates heat transfer for unit cooling. Abnormal thermal and electrical stresses, such as local overheating and electrical discharge ocurring in the transformer, cause decomposition of insulating oil and papers, resulting in production of a range of gases, one of which is hydrogen.

Routine dissolved gas analysis, or DGA, is performed on oil filled transformers to provide a measure of unit health. The process involves the extraction of an oil sample from the transformer, which is then subjected to laboratory analysis. The process is manual, time consuming, and only performed infrequently. It is known that the presence or increasing levels of certain gases is an indicator of internal faults or general wear and tear in a transformer. A reliable stream of data can provide value as a predictive indicator of overall transformer health and maintenance requirements. The endgame is to prevent unit failure and the resultant shutdown of connected customer equipment.

General recommendations call for trend monitoring of hydrogen. The rate of change in the concentration can be more indicative than the overall level in some cases. Any rapid change is a harbinger of potential problems. Adopting a proactive approach, based on transformer oil condition, can extend transformer useful life.

Moisture content of transformer oil is another concern. The presence of water boosts oil and paper insulation deterioration. Water presence in transformers generally has two potential sources, atmospheric and internal. The sources of moisture in the oil are not a subject of this article, but water reduces the dielectric strength of insulating oil and can facilitate corrosion or other material degradation within the transformer case.

Internal temperature is an indicator of the current operating condition of a transformer and is useful in evaluating its performance.

All three of the parameters mentioned, moisture, hydrogen, and temperature, are continuously measured by the new MHT-410 from Vaisala. The transmitter provides three isolated loop powered 4-20 mA outputs that provide the user with continuous data on moisture content, hydrogen concentration, and oil temperature. The compact unit installs easily in less than 30 minutes to provide online monitoring of insulating oil without any need for pumps, membranes, or sampling.

The new MHT410 provides real time transformer health monitoring, as well as information on transformer fault situations. You can find out more with a review of the data sheet included below. Reach out to a

product specialist with your measurement challenges.