The Measurement, Control & Automation Association is the national trade association representing leading manufacturers and distributors of instrumentation, systems and software used in industrial process control and factory automation around the world. Their member companies include the leading multi-national companies together with a range of more niche-oriented providers.

Alliance Technical Sales is very please to be a participating member of such an excellent organization.

An informative and educational resource specializing in process control instrumentation, analytical instruments, and related industrial equipment. Content includes technology basics, how-to's, new product developments, and application notes. Blog is courtesy of Alliance Technical Sales, a leading Manufacturers' Rep headquartered in Clarendon Hills, IL and serving customers in Illinois, Indiana, Iowa, Michigan and Wisconsin.

Brewers, Make Oxygen More Your Friend, and Less Your Enemy. Check Out the Mettler Toledo InTap™ Portable Optical DO analyzer

|

| InTap™ DO Analyzer |

Brewers have a complicated relationship with oxygen.

At times oxygen is your friend. It's needed for barley germination. It's needed to synthesize fatty acids and sterols in yeast. And it improves colloidal stability.

Oxygen is also one of the the brewers worst enemies. It has a significant effect on color. It lowers the rate of wort separation. It can cause undesirable flavors. And is causes haze and makes finished beer stale.

By the way, we're talking about the dissolved oxygen (DO) in solution here. Not the external oxygen the water, wort, or beer tank headspace.

By the way, we're talking about the dissolved oxygen (DO) in solution here. Not the external oxygen the water, wort, or beer tank headspace.

Fortunately Mettler Toledo provides instrumentation to assist brewers in they management of oxygen. Their InTap™ DO analyzer with optical technology, is both a portable measurement tool and a convenient calibration instrument. It facilitates measurement and calibration procedures in both process and laboratory settings, and reduces the risk of operator error.

The InTap™ portable oDO analyzer is a portable measurement device for dissolved oxygen

measurement and for calibration and data logging of optical dissolved oxygen ISM® sensors

(InPro® 6970i) installed in the process. The InTap™ and the sensors communicate via Bluetooth.

Measurement point tracking in the InTap™ portable dissolved oxygen meter allows operators to easily connect stored measurement data to different locations in production, making it easy to maintain records point-by-point for traceability and documentation purposes.

Reliable optical dissolved oxygen (DO) sensor technology is also available in the InTap™ portable meter for spot check and reference measurements. With Blue- tooth communication, hassle-free calibration of in-line DO sensors is done quickly and easily.

For more information, contact Alliance Technical Sales. They can be reached by calling 630-321-9646 or by visiting their web site at https://alliancets.com.

For more information, contact Alliance Technical Sales. They can be reached by calling 630-321-9646 or by visiting their web site at https://alliancets.com.

Tags:

beer,

brewery,

brewing,

Dissolved Oxygen,

DO,

Illinois,

Indiana,

Iowa,

Mettler Toledo,

Wisconsin

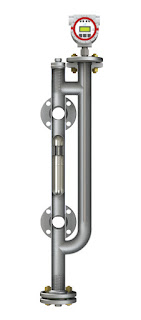

Jogler Dual Chamber Level System

Dual chamber systems are often ideal for magnetic level gauges. The compact design eliminates the need for coaxial probes. Dual chamber systems also allow for multiple redundant technologies, including guided wave radars, capacitance level transmitters, and tuning fork level switches.

Dual chamber systems are often ideal for magnetic level gauges. The compact design eliminates the need for coaxial probes. Dual chamber systems also allow for multiple redundant technologies, including guided wave radars, capacitance level transmitters, and tuning fork level switches.Advantages of Dual Chambers

- Cuts out need for coaxial probes

- A single probe can be easily removed from the chamber for maintenance and cleaning

- Putting a Guided Wave Radar and a float in a single chamber requires larger pipe and flange sizes and a baffled plate between the float and the GWR coaxial probe

Disadvantages of a Single Chamber System

- A magnetic field orientation not optimal for instrument installation

- Radar interference due to the baffled plate

- Float obstruction due to an extra wall in the chamber

- Mandatory use of coaxial probe shields which are susceptible to blockage and fouling leading to

- incorrect measurements

- Increased cost and weight of the system

- Remote mounting of GWR electronics when top connections to the system are necessary

HF scientific Water Quality Measurement Products Catalog

HF scientific produces instrumentation, test kits and chemical reagents used for monitoring water quality in a variety of applications. Their primary market is in the area of Industrial and Municipal water treatment, but their products are also found in industrial process control systems and marine ballast water systems.

HF scientific produces instrumentation, test kits and chemical reagents used for monitoring water quality in a variety of applications. Their primary market is in the area of Industrial and Municipal water treatment, but their products are also found in industrial process control systems and marine ballast water systems.Products Include:

- M100+ Laboratory Turbidimeter

- MTOL+ Online Process Turbidimeter

- ProCal Primary Turbidity Standards for use with the Hach® 1720 c/d/e Series Online Turbidimete

- CLX Online Residual Oxident and Chlorine Monitor

- CLX-Ex Residual Oxidant Monitor for Hazardous Atmospheres

- CLX-Ex2 Extended Reagent Life Online TRO and Chlorine Monitor for Hazardous Atmospheres

- AccUView LED Online UV Analyzer

- J.A.W. Chlorine Reagents

- DPD Reagent Dispensers

- Nitrification Inhibitor Dispensers

LIDAR, Non-contact Level Transmitter for Fast and Accurate Measurement

|

| Jogler LLT-1000 |

Jogler's Lidar Level Transmitter LLT-1000 is a laser-based non-contact instrument that measures the level of silos, tanks, hoppers, chutes and bunkers. The LLT-1000 uses time-of-flight laser technology to measure distance. This principle of quick and accurate measurement provides many benefits over other level measurement techniques.

Alliance Technical Sales, Inc.

630-321-9646

https://alliancets.com

Inline Dissolved Oxygen Sensor Designed for Breweries

|

| InPro6970i for brewing |

The sensor is inserted in the pipe at the start of the filling line, and provides real-time measurements on the oxygen content of the beer. If the oxygen level is too high, the flow of beer is stopped to prevent the out of specification product continuing down the line.

Unlike most dissolved oxygen sensors available, the InPro6970i uses a clever optical technique for measuring oxygen. At the tip of the sensor there's a layer of molecules that absorb and emit light. These molecules are sensitive to oxygen which alters how the molecules behave. The greater the quantity of oxygen, the greater the changes in their behavior. The sensor very accurately measures these changes and sends the signal to the transmitter. This technique is extremely fast and accurate at measuring changes in beer oxygen level, which is why it is favored by breweries. But that is not the only requirement breweries demand. Sensors must be rugged, easy to use, and simple to maintain.The InPro6970i scores highly in all these areas. The sensor's stainless steel body is extremely robust, the unit is easily and quickly installed, and the only maintenance required is the periodic exchange of the oxygen sensitive element, the OptoCap. Intelligent Sensor Management, or ISM, is a feature of the InPro6970i that offers significant benefits to breweries. The sensor can be calibrated in a convenient location such as a lab. Upon connection to the transmitter, the system is ready to measure in only a few seconds, so measurement point down time is very short. The dynamic lifetime indicator uses sophisticated algorithms to calculate the remaining life of the sensor, breweries therefore have confidence that the sensor won't fail unexpectedly.

Contact Alliance Technical Sales for more information. Call 630-321-9646 or visit https://alliancets.com.

Subscribe to:

Comments (Atom)