An informative and educational resource specializing in process control instrumentation, analytical instruments, and related industrial equipment. Content includes technology basics, how-to's, new product developments, and application notes. Blog is courtesy of Alliance Technical Sales, a leading Manufacturers' Rep headquartered in Clarendon Hills, IL and serving customers in Illinois, Indiana, Iowa, Michigan and Wisconsin.

How ISM™ Digital Technology Enhances Quality in Pharmaceutical and Chemical Industries

Learn More About ISM from This Mettler Toledo Video

https://alliancets.com

630-321-9646

The Role of TDL Analyzers in Ensuring Safety and Efficiency in Industrial Processes

How TDLA Works:

- A diode laser emits light at a specific frequency towards the sample gas.

- The sample gas absorbs some of the light depending on the concentration of the specific molecules.

- The remaining light passes through the gas and reaches a detector on the other side.

- The concentration of the gas can be determined by analyzing the intensity of the received light and comparing it to the emitted light.

Advantages of TDLA:

- Non-contact Measurement: TDLAs do not come in direct contact with the gas being analyzed, which is beneficial when the gas might be corrosive or at high temperatures.

- Fast Response: They provide almost real-time measurement, which is crucial in many industrial applications.

- Low Maintenance: They require minimal maintenance due to the lack of moving parts and direct contact with the sample.

- High Sensitivity and Precision: TDLAs can detect even low concentrations of gases with high accuracy.

Industrial Applications of TDLA:

- Power Plants: For measuring oxygen, carbon monoxide, and ammonia concentrations for combustion control and emissions monitoring.

- Petrochemical: In refineries, TDLAs monitor the concentration of different gases in processes such as reforming or ethylene production.

- Steel Industry: For measuring oxygen concentration in blast furnaces or carbon monoxide in coke ovens.

- Cement Industry: To monitor the concentration of gases like carbon monoxide or oxygen in kilns.

- Chemical Production: TDLAs monitor reactant and product concentrations in real time to ensure the optimal production rate.

- Natural Gas Processing: TDLAs measure moisture content, crucial in processing and transporting natural gas.

- Environmental Monitoring: TDLAs can be employed in stack monitoring systems to measure concentrations of pollutants.

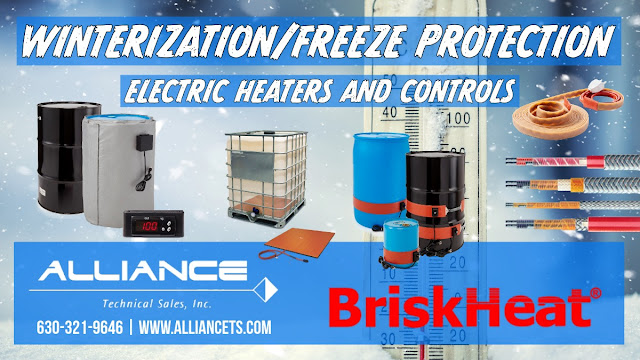

The Crucial Need for Timely Freeze Protection in Modern Commercial and Industrial Facilities

- Drum/Pail Heaters & Insulators

- Wraparound Tote Tank/IBC Heaters & Insulators

- Silicone Rubber Tote Tank/IBC Heater & Control

- Hazardous-Area Rated Silicone Rubber Drum Heater

- XtremeFLEX® Silicone Rubber Heating Tapes

- RKP XtremeFLEX® Silicone Rubber Heating Tapes

- XtremeFLEX® Silicone Rubber Heating Tapes

- Digital Temperature Controllers

- Outdoor Digital Controllers

- Ambient Sensing Capillary Temperature Controllers

- On/Off Thermostats

- Bulb & Capillary Temperature Controllers

- Hazardous-Area Equipment Bulb & Capillary Controllers

- Hazardous-Area Silicone Rubber Heating Blankets

- Heavy-Duty Silicone Rubber Heating Blankets

- Standard-Duty Silicone Rubber Heating Blankets

- Enclosure Heaters

- Crankcase Heaters for HVAC/R Compressors

- Mica Band & Nozzle Heaters

- Screw Plug Immersion Heaters

- Immersion Cartridge Heaters

Process Analytics: Measuring and Controlling Vital Parameters in Industrial Applications

What is Process Analytics?

pH

Oxidation-Reduction Potential (ORP)

Dissolved and Gaseous Oxygen

Dissolved CO2

Ozone

Conductivity

Turbidity

The Role of Process Analytics

From Safety to Efficiency: Why Industrial Electric Tote Heaters are Key in Process Plants

- Process Optimization: Many industrial processes require specific temperature maintenance for optimal efficiency. If the temperature is too low or too high, the process might not work as effectively or be damaged. IBC tote heaters ensure that the materials remain at the optimal temperature throughout the process.

- Preventing Material Solidification: Certain materials, such as certain oils, chemicals, or foodstuffs, can solidify or thicken at low temperatures, making them difficult to work with or damaging equipment. Tote heaters can prevent this from happening by maintaining a stable temperature.

- Improving Material Flow: By maintaining or increasing the temperature of the materials, tote heaters can improve the flow of viscous materials, making processes more efficient and preventing blockages in machinery.

- Safety: In some cases, materials might need to be kept at a specific temperature to prevent them from becoming hazardous. For example, certain chemicals might become volatile or corrosive if they get too cold or too hot. Tote heaters can help maintain a safe temperature.

- Product Quality: Maintaining the correct temperature can also be necessary to ensure the final product's quality. For example, a food product at the wrong temperature could spoil or develop off-flavors.

- Cost-Efficiency: Electric tote heaters are often more energy-efficient than other heating methods, which can save money in the long term. They also provide uniform heat distribution, which is more efficient and prevents hotspots.

- Flexibility: Many electric tote heaters are adjustable and portable, quickly moved between different totes or adjusted to accommodate other materials or process requirements.

LIDAR Non-contact Level Transmitters

LIDAR (Light Detection and Ranging) level transmitters are a type of sensor that uses laser technology to measure the distance between the sensor and the surface of a material. They are used in various industrial applications to detect the level of materials in a process. Here are some of the benefits of using these devices:

- High Accuracy: LIDAR level transmitters can provide accurate measurements, often down to the millimeter level, making them highly effective for precise measurement tasks.

- Non-Contact Measurement: These devices use lasers for measurement, so they do not need to touch the material physically, making them ideal for use with corrosive, hot, or otherwise hazardous materials.

- Versatile: LIDAR level transmitters measure the level of a wide range of materials, including solids, liquids, and sludges.

- Long Range: These devices can typically measure distances up to several hundred meters, making them suitable for use in large tanks and silos.

- Real-Time Monitoring: LIDAR level transmitters can provide real-time level data, automating processes and improving efficiency.

- Resistance to Interference: Unlike other types of sensors, LIDAR level transmitters are unaffected by dust, steam, or other environmental factors, making them reliable even in difficult operating conditions.

- Low Maintenance: These devices generally require less maintenance than other level sensors due to their non-contact nature.

LIDAR level transmitters are typically best suited for materials that have a relatively flat and reflective surface, as this allows the laser reflection back to the sensor. They are effective with various materials, including multiple liquids (like water, oil, and chemicals), bulk solids (like grain, coal, and plastic pellets), and even sludges or slurries. However, they may not be as effective with highly absorbent materials or have a very uneven surface, as this can scatter the laser light and make it difficult for the sensor to detect the reflection.

https://alliancets.com

630-321-9646

Smart Planning: Tackle Your Freeze Protection Winterization in the Warm Season

Piping systems, valves, tanks, vessels and gutters require freeze protection in cold weather. The term winterization refers to safeguarding these components against freezing temperatures. The winter season presents numerous challenges for property and business owners, particularly in protecting their structures from freezing temperatures, snow, and ice. Frozen pipes, gutters, and roofs during winter can damage property. Utilizing freeze protection products like heat trace systems, roof, gutter kits, and insulation can effectively safeguard you and your property from harsh weather conditions in various ways.

But when should your freeze protection preventive maintenance effort begin?

Let's discuss undertaking winterization during the non-winter months, a prudent strategy for several reasons:

- Mild weather conditions provide better access to areas requiring winterization, ensuring a thorough and efficient process.

- Performing winterization in advance allows for careful planning and assessment of the facility's needs, minimizing the chances of overlooking vulnerabilities.

- It enables businesses to schedule professional services during periods of lower demand, which can lead to cost savings and better availability of resources.

Ultimately, by proactively winterizing facilities during non-winter months, companies can reduce downtime and costly repairs caused by freezing temperatures and other winter-related issues, ensuring the smooth operation of their industrial plants and factories throughout the colder months.

Easy Access

Setting up freeze protection solutions in mild weather conditions enables effortless access to the installation locations. In comparison, winter months may cause these areas to be obstructed by snow or ice, making access challenging or hazardous. Taking a proactive approach ensures you protect property without jeopardizing your safety or that of others.

Strategic Planning and Readiness

Implementing freeze protection solutions during warmer periods allows you to strategize and prepare for the upcoming winter, minimizing potential stress and eliminating the need for rushed decisions. You can evaluate your property's requirements and choose the most suitable solutions. Additionally, you can engage a professional to guarantee proper and efficient installation.

Financial Benefits

Opting for freeze protection solutions in warmer months may save long-term costs. You can avert emergency repair expenses that tend to be considerably higher during winter when the demand for such services and products peaks.

Damage Prevention

Setting up freeze protection solutions before winter arrives helps avert property damage caused by freezing temperatures. It spares you the inconvenience and costs of adequately preparing for unfavorable issues.

In summary, opting for freeze protection solutions during warmer months is a forward-thinking strategy for safeguarding your property against the detrimental impacts of freezing temperatures. By planning proactively and taking early action, you can ultimately save time and money and reduce stress in the long term.

The Mettler Toledo InPro X1 HLS is a Digital, Food-safe, In-line pH Sensor

pH measurement is essential in the food and beverage industry to ensure food safety, maintain product quality and consistency, optimize taste and flavor, comply with regulations, control chemical reactions, and preserve nutrient content.

The Mettler Toledo InPro X1 HLS pH sensor is designed specifically for Food & Beverage applications. The InPro X1 HLS construction includes high-quality materials that make it highly durable and more applicable than a glass pH sensor.

The InPro X1 HLS:

- Resists Clean-in-Place Processes - The InPro X1 HLS is the premier food-safe, in-line pH sensor, maintaining accuracy and longevity without compromising its ability to withstand cleaning processes.

- Improves Product Yield and Quality - Accurate in-line pH measurement enables absolute process control, resulting in enhanced product quality, increased yield, and reduced batch times.

- Meets All Major Food Regulations - The InPro X1 HLS features a hygienic design, using materials chosen explicitly for food and beverage contact applications, and holds certifications such as 3A, EHEDG, EC1935/2004, ATEX, and FM.

- Eliminates Risk of Glass Contamination - The unbreakable X-Chip pH-sensing technology allows for in-line pH measurement without the hazard of glass fragment contamination.

Why is pH Measurement Critical for the Food and Beverage Processing Industry?

- Food safety and shelf life: pH levels can affect the growth of microorganisms, such as bacteria, yeast, and mold. A lower pH (higher acidity) usually inhibits the growth of harmful organisms, improving food safety and extending shelf life. Measuring and controlling pH can help prevent spoilage and ensure the safety of products.

- Product quality and consistency: pH significantly impacts the taste, texture, and appearance of food and beverages. It can influence enzymatic reactions, protein denaturation, and Maillard browning reactions. Manufacturers can maintain product quality and consistency across different batches by controlling pH.

- Flavor and taste: pH affects the taste profile of food and beverages. For example, acidic products (lower pH) have a sour taste, while basic products (higher pH) tend to taste bitter. Balancing pH is essential to achieving the desired flavor profile and consumer acceptance.

- Regulatory compliance: Food and beverage industries must adhere to strict regulations and guidelines, which often include specific pH requirements. Meeting these regulations ensures that products are safe for consumption and reduces the risk of product recalls.

- Chemical reactions: pH influences the rate and extent of chemical reactions in food and beverage products, such as fermentation, emulsification, and gelation. Manufacturers can optimize these reactions by monitoring and controlling pH to achieve the desired product characteristics.

- Nutrient availability and stability: pH levels can influence the stability and availability of nutrients, such as vitamins and minerals, in food and beverages. Controlling pH can help maintain nutrient content and improve the nutritional value of products.