"Christmas gift suggestions: To your enemy, forgiveness. To an opponent, tolerance. To a friend, your heart. To a customer, service. To all, charity. To every child, a good example. To yourself, respect." — Oren Arnold

An informative and educational resource specializing in process control instrumentation, analytical instruments, and related industrial equipment. Content includes technology basics, how-to's, new product developments, and application notes. Blog is courtesy of Alliance Technical Sales, a leading Manufacturers' Rep headquartered in Clarendon Hills, IL and serving customers in Illinois, Indiana, Iowa, Michigan and Wisconsin.

What Are Direct-reading Level Gauges, Site Flow Indicators, and Specific Gravity Analyzers?

|

| Direct-reading Level Gauges (Jogler) |

Direct-reading Level Gauges

Direct-reading Level Gauges are the simplest, most reliable way to determine the level of liquid in a tank or vessel because they give you a direct view without compromising the integrity of your process system. Direct-Reading level gauges are installed so that the liquid level in the transparent sight tube is always the same as the liquid level inside the tank or vessel.

Sight Flow Indicators

|

| Sight Flow Indicators (Jogler) |

Sight Flow Indicators are the simplest, most reliable way to observe liquid or solids flow without compromising the integrity of your piping system. They are available in either armored styles for protection in exposed locations, or lantern styles for 360-degree viewing.

Specific Gravity Analyzers (SGAs)

|

| Specific Gravity Analyzer (Jogler) |

- Acids

- Caustics

- Co-generation

- Light Hydrocarbons

- Beverages, etc.

DOWNLOAD THE JOGLER LEVEL GAUGE, FLOW INDICATOR & ANALYZER BROCHURE HERE

For more information on these products, contact Alliance Technical Sales by calling 630-321-9646 or visit their web site at https://alliancets.com.

Validating Water Cycle pH Requirements Using Conductivity and Calculated pH

In thermal power plants, pH measurement and control in the water steam cycle are critical to minimizing corrosion. Cycle chemistry guidelines specifically target narrow pH ranges.

However, in high purity water and steam, there are not enough ions in the water to generate a pH response, causing the pH reading to be unstable. Fortunately, conductivity has a direct relationship with pH when the sample contains only pure water with the typical alkaline treatments, such as ammonia and amines. In fact, cycle chemistry in many plants relies primarily on the related specific conductivity values. However, correction for minor contaminants by measuring the cation conductivity of the sample is needed to provide accurate results. The specific and the cation conductivity values are used in an industry accepted calculation that provides the highest accurate conversion to pH. Under normal operating conditions, this calculation provides more accurate and reliable results than pH electrodes can provide, for two reasons:

- Conductivity is linear, with concentration which provides much higher resolution than pH sensors all of which give nonlinear response to concentration.

- Conductivity sensors can be directly calibrated with minimal introduction of error.

This makes calculated pH based on conductivity significantly more accurate. However, with major contamination, such as when a condensate exchange polisher's resin is exhausted, and an acid leak occurs, the pH would drop below 7, which is outside the ideal range for using calculated pH and would generate errors. Thus, to avoid contamination, it is recommended that both traditional pH measurement, and calculated pH based on conductivity, be used for optimal pH control.

METTLER TOLEDO Thornton's M800 multi-parameter transmitter can provide traditional pH measurement, calculated pH, as well as specific and cation conductivity to ensure accurate and reliable pH control. The M800 even has a built-in alarm to alert you if the pH measurement deviates from the calculated pH measurement for extra security and peace of mind.

For more infomration about METTLER TOLEDO Process Analytics products, contact Alliance Technical Sales by calling 630-321-9646 or by visiting https://alliancets.com.

Thank You Veterans for Your Patriotism, Love of Country, and Willingness to Serve

Veterans Day is not just another holiday. It honors those Americans who fought for our freedom. By celebrating our Veterans, we continue to tell the story of how this country became the most powerful on Earth - through bravery, honor, truth, and determination.

Our Veterans are our neighbors, friends, family, and co-workers. They took an oath to defend the United States and our Constitution, from all enemies, foreign and domestic. We must never forget their bravery, service, and sacrifice.

Alliance Technical Sales thanks our Veterans, past and present, for serving our country and protecting our freedom.

No More Purge Gas Required for New Tunable Diode Lasers for Combustion Processes

A new generation of TDLs not only offers exceptional fuel costs savings, but eliminates the need for process side purge gas.

Refineries, petrochemical, fertilizer and power plants worldwide have large numbers of combustion processes in operation, from process heaters and fired heaters to package boilers and large steam turbines. Whenever a process fluid needs to be heated as part of a chemical reaction, or there is a requirement for steam generation, there will be a combustion process at its heart.

This paper presents a review of the general anatomy of a typical combustion process; describing each zone and its function, before discussing some of the challenges of combustion measurement and how modern TDL analyzers such as METTLER TOLEDO’s GPro 500 and its range of process adaptions offer many advantages over typical combustion analysis technologies.

For more information about GPro® 500 TDL, contact Alliance Technical Sales by calling 630-321-9646 or by visiting https://alliancets.com.

Proper Installation of BriskHeat XtremeFLEX Heating Tape

BriskHeat XtremeFlex heating tape is very versatile due to its superior flexibility. Although it is versatile, there can still be failures in hotspots if it's not properly installed. The purpose of this short video is to help you avoid failures and hot spots, and to help you install your heating tape for optimal performance.

Before you get started there's a few things that you should keep in mind:

- Make sure you have these tools prior to installing the heating tape - Gloves, Heating Tape, Heat Conductive Putty, Scissors, Fiberglass Tape.

- Be sure that the surface that you're applying the heat tape to is clean, dry, and free of burrs, oils, debris or sharp edges.

- Ensure that you don't overlap the heating tape onto itself leave at least an eighth of inch gap between each wrap.

You also want to ensure complete surface contact between the heating tape and the surface. Air gaps can cause hotspots which can result in premature failures to the heating tape. Use our heat conductive putty to bridge any gaps between the heating tape and the surface. When working with heat conductive putty, wear proper personal protective equipment. Place a fair amount of putty where the transitions meet so that there will not be any air gaps when installing. With many heating tapes you will need a temperature controller device, so contact your BriskHeat Representative for assistance.

To make sure that the heat tape stays in place use briskets high-temperature fiberglass adhesive tape or high-temperature aluminum adhesive tape because it will not damage the heating tape and it can withstand the high temperature that the heating tape produces. Use insulation on BriskHeat heating products in order to avoid heat loss.

For more information about the BriskHeat heating products, contact Alliance Technical Sales.

Phone: 630-321-9646

The Mettler Toledo GPro® 500 Series of Tunable Diode Lasers

Tunable Diode Lasers (TDLs) use a measurement technology called absorption spectroscopy: they output a beam of laser light at the same frequency that the gas to be measured absorbs light. The TDL analyzes the light after it has passed through the gas stream and calculates the quantity of the target gas in the stream. The use of TDL sensors is becoming more and more common in industrial processes.

Mettler Toledo manufactures the GPro® 500 TDL Series of Tunable Diode Laser designed for the toughest gas measurements. These analyzers are known to handle some of the most demanding process applications, particularly where accuracy and fast response is crucial.

Using a modular design, the GPro® 500 tunable diode laser gas analyzer allows you to select the process adaption that fits your application, and match it with the parameter that you need to measure. We offer sensors that measure a variety of gases including Carbon Dioxide (CO₂), Carbon Monoxide (CO), Hydrogen Chloride (HCl), Hydrogen Sulfide (H₂S), Moisture, Ammonia (NH₃), Methane (CH₄) and Oxygen (O₂).

GPro® 500 Tunable Diode Laser - Eliminate Alignment

Most TDLs are comprised of two parts: the laser source unit and a receiving/analyzing unit. These parts must be installed directly opposite each other, which is not always easy and misaligned can often occur. METTLER TOLEDO's GPro® 500 Series solves this by combining both parts in a single unit. A probe attached to the GPro® sensor protrudes into the gas stream. A three-sided mirror at the end of the probe directs the beam back through the probe to the receiver, so alignment is always perfect.

Most TDLs are comprised of two parts: the laser source unit and a receiving/analyzing unit. These parts must be installed directly opposite each other, which is not always easy and misaligned can often occur. METTLER TOLEDO's GPro® 500 Series solves this by combining both parts in a single unit. A probe attached to the GPro® sensor protrudes into the gas stream. A three-sided mirror at the end of the probe directs the beam back through the probe to the receiver, so alignment is always perfect.GPro® 500 Tunable Diode Laser - Minimal Maintenance

The GPro® does not require "maintenance intensive" extractive and conditioning systems. This means that you receive consistent performance from your tunable diode laser gas analyzer without the downtime and cost associated with these traditional systems. You achieve reliable uptime, critical in safety applications, at a reduced cost of ownership.

The GPro® does not require "maintenance intensive" extractive and conditioning systems. This means that you receive consistent performance from your tunable diode laser gas analyzer without the downtime and cost associated with these traditional systems. You achieve reliable uptime, critical in safety applications, at a reduced cost of ownership.For more information about the Mettler Toledo GPro® 500 Tunable Diode Laser, contact Alliance Technical Sales.

Phone: 630-321-9646

Web: https://alliancets.com

Alliance Technical Sales Celebrating 5 Year Anniversary with MCAA!

The Measurement, Control & Automation Association is the national trade association representing leading manufacturers and distributors of instrumentation, systems and software used in industrial process control and factory automation around the world. Their member companies include the leading multi-national companies together with a range of more niche-oriented providers.

Alliance Technical Sales is very please to be a participating member of such an excellent organization.

Alliance Technical Sales is very please to be a participating member of such an excellent organization.

Brewers, Make Oxygen More Your Friend, and Less Your Enemy. Check Out the Mettler Toledo InTap™ Portable Optical DO analyzer

|

| InTap™ DO Analyzer |

Brewers have a complicated relationship with oxygen.

At times oxygen is your friend. It's needed for barley germination. It's needed to synthesize fatty acids and sterols in yeast. And it improves colloidal stability.

Oxygen is also one of the the brewers worst enemies. It has a significant effect on color. It lowers the rate of wort separation. It can cause undesirable flavors. And is causes haze and makes finished beer stale.

By the way, we're talking about the dissolved oxygen (DO) in solution here. Not the external oxygen the water, wort, or beer tank headspace.

By the way, we're talking about the dissolved oxygen (DO) in solution here. Not the external oxygen the water, wort, or beer tank headspace.

Fortunately Mettler Toledo provides instrumentation to assist brewers in they management of oxygen. Their InTap™ DO analyzer with optical technology, is both a portable measurement tool and a convenient calibration instrument. It facilitates measurement and calibration procedures in both process and laboratory settings, and reduces the risk of operator error.

The InTap™ portable oDO analyzer is a portable measurement device for dissolved oxygen

measurement and for calibration and data logging of optical dissolved oxygen ISM® sensors

(InPro® 6970i) installed in the process. The InTap™ and the sensors communicate via Bluetooth.

Measurement point tracking in the InTap™ portable dissolved oxygen meter allows operators to easily connect stored measurement data to different locations in production, making it easy to maintain records point-by-point for traceability and documentation purposes.

Reliable optical dissolved oxygen (DO) sensor technology is also available in the InTap™ portable meter for spot check and reference measurements. With Blue- tooth communication, hassle-free calibration of in-line DO sensors is done quickly and easily.

For more information, contact Alliance Technical Sales. They can be reached by calling 630-321-9646 or by visiting their web site at https://alliancets.com.

For more information, contact Alliance Technical Sales. They can be reached by calling 630-321-9646 or by visiting their web site at https://alliancets.com.

Tags:

beer,

brewery,

brewing,

Dissolved Oxygen,

DO,

Illinois,

Indiana,

Iowa,

Mettler Toledo,

Wisconsin

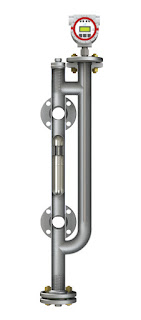

Jogler Dual Chamber Level System

Dual chamber systems are often ideal for magnetic level gauges. The compact design eliminates the need for coaxial probes. Dual chamber systems also allow for multiple redundant technologies, including guided wave radars, capacitance level transmitters, and tuning fork level switches.

Dual chamber systems are often ideal for magnetic level gauges. The compact design eliminates the need for coaxial probes. Dual chamber systems also allow for multiple redundant technologies, including guided wave radars, capacitance level transmitters, and tuning fork level switches.Advantages of Dual Chambers

- Cuts out need for coaxial probes

- A single probe can be easily removed from the chamber for maintenance and cleaning

- Putting a Guided Wave Radar and a float in a single chamber requires larger pipe and flange sizes and a baffled plate between the float and the GWR coaxial probe

Disadvantages of a Single Chamber System

- A magnetic field orientation not optimal for instrument installation

- Radar interference due to the baffled plate

- Float obstruction due to an extra wall in the chamber

- Mandatory use of coaxial probe shields which are susceptible to blockage and fouling leading to

- incorrect measurements

- Increased cost and weight of the system

- Remote mounting of GWR electronics when top connections to the system are necessary

HF scientific Water Quality Measurement Products Catalog

HF scientific produces instrumentation, test kits and chemical reagents used for monitoring water quality in a variety of applications. Their primary market is in the area of Industrial and Municipal water treatment, but their products are also found in industrial process control systems and marine ballast water systems.

HF scientific produces instrumentation, test kits and chemical reagents used for monitoring water quality in a variety of applications. Their primary market is in the area of Industrial and Municipal water treatment, but their products are also found in industrial process control systems and marine ballast water systems.Products Include:

- M100+ Laboratory Turbidimeter

- MTOL+ Online Process Turbidimeter

- ProCal Primary Turbidity Standards for use with the Hach® 1720 c/d/e Series Online Turbidimete

- CLX Online Residual Oxident and Chlorine Monitor

- CLX-Ex Residual Oxidant Monitor for Hazardous Atmospheres

- CLX-Ex2 Extended Reagent Life Online TRO and Chlorine Monitor for Hazardous Atmospheres

- AccUView LED Online UV Analyzer

- J.A.W. Chlorine Reagents

- DPD Reagent Dispensers

- Nitrification Inhibitor Dispensers

LIDAR, Non-contact Level Transmitter for Fast and Accurate Measurement

|

| Jogler LLT-1000 |

Jogler's Lidar Level Transmitter LLT-1000 is a laser-based non-contact instrument that measures the level of silos, tanks, hoppers, chutes and bunkers. The LLT-1000 uses time-of-flight laser technology to measure distance. This principle of quick and accurate measurement provides many benefits over other level measurement techniques.

Alliance Technical Sales, Inc.

630-321-9646

https://alliancets.com

Inline Dissolved Oxygen Sensor Designed for Breweries

|

| InPro6970i for brewing |

The sensor is inserted in the pipe at the start of the filling line, and provides real-time measurements on the oxygen content of the beer. If the oxygen level is too high, the flow of beer is stopped to prevent the out of specification product continuing down the line.

Unlike most dissolved oxygen sensors available, the InPro6970i uses a clever optical technique for measuring oxygen. At the tip of the sensor there's a layer of molecules that absorb and emit light. These molecules are sensitive to oxygen which alters how the molecules behave. The greater the quantity of oxygen, the greater the changes in their behavior. The sensor very accurately measures these changes and sends the signal to the transmitter. This technique is extremely fast and accurate at measuring changes in beer oxygen level, which is why it is favored by breweries. But that is not the only requirement breweries demand. Sensors must be rugged, easy to use, and simple to maintain.The InPro6970i scores highly in all these areas. The sensor's stainless steel body is extremely robust, the unit is easily and quickly installed, and the only maintenance required is the periodic exchange of the oxygen sensitive element, the OptoCap. Intelligent Sensor Management, or ISM, is a feature of the InPro6970i that offers significant benefits to breweries. The sensor can be calibrated in a convenient location such as a lab. Upon connection to the transmitter, the system is ready to measure in only a few seconds, so measurement point down time is very short. The dynamic lifetime indicator uses sophisticated algorithms to calculate the remaining life of the sensor, breweries therefore have confidence that the sensor won't fail unexpectedly.

Contact Alliance Technical Sales for more information. Call 630-321-9646 or visit https://alliancets.com.

Oil & Gas and Power Grids Have New "Cause for Concern" from Hackers

A report released in June, from the security firm Dragos, describes a worrisome development by a hacker group named, “Xenotime” and at least two dangerous oil and gas intrusions and ongoing reconnaissance on United States power grids.

Multiple ICS (Industrial Control Sectors) sectors now face the XENOTIME threat; this means individual verticals – such as oil and gas, manufacturing, or electric – cannot ignore threats to other ICS entities because they are not specifically targeted.

The Dragos researchers have termed this threat proliferation as the world’s most dangerous cyberthreat since an event in 2017 where Xenotime had caused a serious operational outage at a crucial site in the Middle East.

The fact that concerns cybersecurity experts the most is that this hacking attack was a malware that chose to target the facility safety processes (SIS – safety instrumentation system).

For example, when temperatures in a reactor increase to an unsafe level, an SIS will automatically start a cooling process or immediately close a valve to prevent a safety accident. The SIS safety stems are both hardware and software that combine to protect facilities from life threatening accidents.

At this point, no one is sure who is behind Xenotime. Russia has been connected to one of the critical infrastructure attacks in the Ukraine. That attack was viewed to be the first hacker related power grid outage.

This is a “Cause for Concern” post that was published by Dragos on June 14, 2019.

“While none of the electric utility targeting events has resulted in a known, successful intrusion into victim organizations to date, the persistent attempts, and expansion in scope is cause for definite concern. XENOTIME has successfully compromised several oil and gas environments which demonstrates its ability to do so in other verticals. Specifically, XENOTIME remains one of only four threats (along with ELECTRUM, Sandworm, and the entities responsible for Stuxnet) to execute a deliberate disruptive or destructive attack.

XENOTIME is the only known entity to specifically target safety instrumented systems (SIS) for disruptive or destructive purposes. Electric utility environments are significantly different from oil and gas operations in several aspects, but electric operations still have safety and protection equipment that could be targeted with similar tradecraft. XENOTIME expressing consistent, direct interest in electric utility operations is a cause for deep concern given this adversary’s willingness to compromise process safety – and thus integrity – to fulfill its mission.

XENOTIME’s expansion to another industry vertical is emblematic of an increasingly hostile industrial threat landscape. Most observed XENOTIME activity focuses on initial information gathering and access operations necessary for follow-on ICS intrusion operations. As seen in long-running state-sponsored intrusions into US, UK, and other electric infrastructure, entities are increasingly interested in the fundamentals of ICS operations and displaying all the hallmarks associated with information and access acquisition necessary to conduct future attacks. While Dragos sees no evidence at this time indicating that XENOTIME (or any other activity group, such as ELECTRUM or ALLANITE) is capable of executing a prolonged disruptive or destructive event on electric utility operations, observed activity strongly signals adversary interest in meeting the prerequisites for doing so.”

Heating Tapes: Application and Installation Tips

|

| High temperature tape (left) and moisture & chemical resistant tape (right). |

Heating tapes are easy-to-use, ideal for a wide range of thermal applications, and inexpensive. This article will provide simple installation tips to improve your heating tape product life, application performance, and most importantly, your safety.

Why Heating Tapes?

Heating tapes offer many advantages for solving a wide range of gas, liquid, and solid heating applications.

Advantages:

- Flexibility: Easily installs directly to a wide variety of surfaces and geometries (i.e. 1/4” diameter or larger piping, glassware, valves, reactors, chambers, etc.)

- Rapid and uniform heat-up due to high watt densities and user-configurable installations

- High temperature ranges

- Easily controlled with standard temperature controlling devices

- Variety of sizes, wattages, temperature ranges, and styles available to meet your exact heating requirements

|

| Always follow the manufacturer’s instructions while installing or removing heating tape. |

Step 1: Preparation

Prepare surface to be heated: Wipe the surface making sure there is no foreign material, like liquid, on the surface. Foreign material inhibits heat transfer and liquid can damage select models of heating tape (i.e. High-Temperature Heating Tapes).

Make a visual inspection of heating tape: We recommend that you replace the heating tape if it becomes torn or damaged. Damaged heating tape is a safety hazard and will not operate correctly.

Selecting the Proper Heating Tape

|

| Figure B |

Selection of your tape depends on:

- Length, diameter, and configuration of the surface to be heated

- Required temperature

- Required wattage

- Environmental conditions (i.e. likelihood heating tape will come into contact with moisture or chemicals)

Step 2: Installing your Heating Tape

|

| Figure C |

Heating tape can be installed on nearly any surface due to its flexibility. Spiral wrap the heating tape onto the surface to be heated so that the length of one entire side of the heating tape is in full contact with the surface (Figure B). The distance between spiral wraps is dependent on the uniformity requirements and the amount of available heating tape. A minimum distance of 1/8” is required between spiral wraps to avoid damage to the heating tape.

Attach the heating tape to the surface by either using built-in tie straps (Figure C), high-temperature adhesive tape (Figure D), or mechanical clamping devices that will not cause damage to the heating tape.

|

| Figure D |

Ensure the heating tape is not kinked, twisted, or hanging free from the surface (Figure E and F). Do not overlap heating tape on itself (Figure G). This can cause damage to the heating tape due to overheating.

Do's

- Make sure you have selected the correct heating tape for your application. BriskHeat offers a wide range of sizes, voltages, and temperature ranges.

- Visually check your heating tape prior to use.

- Make sure that the heating tape makes full contact with the surface to be heated.

- Always follow the manufacturer’s instructions while installing or removing heating tape.

|

| Don't kink or overlap, apply without control, apply over insulation, never use near flammable materials, do not submerge, and do not use if tape is cut or damaged. |

- Do not overlap the heating tape over itself

- Do not use heating tape without a controlling device

- Do not install heating tape on top of insulation near flammable materials, submerged in liquids, or if cut in any way.

For more information about heat tapes, or any industrial heating application, contact Alliance Technical Sales by calling 630-321-9646 or by visiting https://alliancets.com.

Safety, Quality, Productivity: Rethinking Gas Analytics Across Process Industries

Mettler Toledo Process Analytics designs analyzers and sensors based around a simple concept – how can the design, handling, and maintenance of their products help you improve quality, productivity, and safety? This led to their rethinking gas analytics and the development of a unique portfolio of gas instruments that offers you faster measurements, greater process availability, and unequalled ease of use.

The Mettler Toledo GPro® 500 TDL O2, CO, CO2 and moisture analyzers are designed for ease of installation and low maintenance operation in a wide variety of process applications in the refining, petrochemical, and associated process industries.

The GPro® 500 oxygen gas analyzer is a unique tunable diode laser spectrometer designed for safety applications. It uses a folded-path laser beam design for simple installation and measurement.

Applications covered in the eBook include:

The Mettler Toledo GPro® 500 TDL O2, CO, CO2 and moisture analyzers are designed for ease of installation and low maintenance operation in a wide variety of process applications in the refining, petrochemical, and associated process industries.

The GPro® 500 oxygen gas analyzer is a unique tunable diode laser spectrometer designed for safety applications. It uses a folded-path laser beam design for simple installation and measurement.

GPro® 500 Overview:

- Ideal for applications such as: flare safety control, combustion control, chlorination and oxychlorination, process control, ESP filter production, vent headers, inertization and vapor recovery.

- Is installed in situ, so you get a quick response without the need to extract and condition a sample. This provides a fast response time so that you can make real-time reactions to out-of-spec conditions.

- Is configurable, enabling the oxygen gas analyzer's measurement system to be paired with a variety of process adaptions to meet a wide range of installation requirements.

- Uses Intelligent Sensor Management (ISM®) technology to offer predictive diagnostics on analyzer condition, including informing you when cleaning of the optical path will be required.

Applications covered in the eBook include:

- Direct Chlorination

- VCM Waste Gas Recovery

- FCC Units

- Electrostatic Precipitators

- Formaldehyde Production

- Formaldehyde Production

For more information about GPro® 500 TDL O2, CO, CO2 and moisture analyzers, contact Alliance Technical Sales by calling 630-321-9646 or by visiting https://alliancets.com.

Industrial, Inline, Process Refractometers

Industrial inline refractometers use of the principle of refractometry to assess the physical qualities of fluid. Using the device, the refractive index of the fluid is measured, which indicates whether the product is according to specification. The fundamental physical property helps in determining the purity and composition of fluids.

Refractometers: An Overview

Refractometers are based on the principle of refractometry. The device measures the speed of a ray of light as it crosses from one medium to another. When light travels across two different media, its density and direction change. The change in direction is known as refraction.

Every material has a different refractive index (RI) that refers to the ratio of the velocity of light in a vacuum to the velocity in a specific medium.

Light travels faster in a medium with a lower optical density, resulting in a low reflective index. The lower the optical density of the medium, the lower will be the refractive index due to the higher speed of light. This principle of refractometry is used in various industrial processes for measuring different characteristics of a fluid such as:

- Hydrocarbon content

- Salinity

- Sugar concentration

- Protein concentration

Application of Refractometry in Industries

Refractometry is used in many different industries. Let’s look at the application of the technique of different industrial processes.

Food and Beverage Industry

Refractometry is commonly used in the beverage and food industry for quality control purposes. The technique helps in determining the purity and consistency of processed foods such as vegetables, jams, coffee, and dairy products.

Refractometry is commonly used in the beverage and food industry for quality control purposes. The technique helps in determining the purity and consistency of processed foods such as vegetables, jams, coffee, and dairy products.

The three important parameters that are assessed by refractometers in food processing. They include sugar percentage, acidity, and gelling agent concentration. These parameters are assessed to ensure the right mix that results in maximum shelf life.

The device is used for the measurement of percentage by weight of sugar in fruit juice. The measurement is also known as Brix. Accurate Brix measurement is critical for quality and cost control. The measurement can be carried out by assessing the density and refractive index. Both the parameters provide valuable insight into the content of the fruit.

Chemical Industry

Refractometry is also used for assessing the concentration of a range of chemicals in industries other than food and beverage. Sensors on refractometers installed on large tank, pipes, and reactor can determine the concentration of dissolved solids by optical measurement of the refractive index. The measurement is not influenced by bubbles, particles, temperature changes, or color of the liquid.

Oil Refineries

Oil refineries also rely on refractometers to determine the quality of the oil. Refractive index is used to know the identity of the oil immediately. This method helps in quickly checking the oil that is transferred to the storage facility.

Fertilizer Industry

Fertilizer industry also uses refractometry for assessing the quality of fertilizer solution. Density and refractive index are analyzed to find out the nitrogen concentration in the fertilizer. The method can help in assessing the quality of fertilizers easily, safely, and cost-effectively as compared to the manual method.

Pulp and Paper

Pulp and paper mills use industrial refractometers for green liquor and black liquor processing. Green liquor and black liquor are both part of the Kraft Process whereby wood chips are broken down into their chemical constituents and wood pulp.

Other Users of Refractometry

Refractometry is used in many other industries such as the perfume industry, coolants, lubricants industry, and the milk industry. The process helps in determining the quality and concentration of fluids in different industries.

Contact Alliance Technical Sales with any questions about the application of process refractometers. They can be reached by phone at 630-321-9646 or by visiting https://alliancets.com.

Old Pharmaceutical Reactor Brought Back to Life with New Control System

A bioprocess control system update helped a leading manufacturer of USDA-licensed biologicals improve batch consistency. The pharmaceutical manufacturer had an 800 liter, 30+ year-old stainless steel, steam-in-place (SIP) reactor that was mechanically sound but in desperate need of a new controller. They needed to replace the production capability and required flexible controls for the varying products their customers produced. Of foremost concern was the cost to replace the idle system. ILS Automation came to their rescue.

A bioprocess control system update helped a leading manufacturer of USDA-licensed biologicals improve batch consistency. The pharmaceutical manufacturer had an 800 liter, 30+ year-old stainless steel, steam-in-place (SIP) reactor that was mechanically sound but in desperate need of a new controller. They needed to replace the production capability and required flexible controls for the varying products their customers produced. Of foremost concern was the cost to replace the idle system. ILS Automation came to their rescue.Alliance Technical Sales

630-321-9646

https://alliancets.com

Alliance Technical Sales Products

By combining world-class products, application expertise, and unsurpassed customer service, Alliance Technical Sales enables its clients to increase manufacturing efficiency, reduce production costs, and improve product quality and value. Each of the manufacturers we represent has extensive experience solving critical service applications with the products they manufacture.

Alliance Technical Sales, Inc.

https://alliancets.com

630-321-9646

Hazardous-area Approved Silicone Rubber Heating Blankets For Electrical Surface Heating in Hazardous Locations

Hazardous-area approved silicone rubber heating blankets for electrical surface heating in hazardous locations are available from BriskHeat. They provide a low profile heater design and are ideal for heating surfaces like tanks, hoppers, conveyors, silos, etc.

Silicone rubber heaters provide exceptional durability and longevity, plus moisture, chemical and radiation resistant. They are composed of heavy duty, extra thick silicone rubber which provides exceptional durability and longevity. Available with industrial strength pressure sensitive adhesive backing for easy installation and a patented grounded heating element for your safety meets NEC 427.23.

The resistance heating element is laminated between 4 layers of heavy duty fiberglass reinforced silicone rubber; two layers of 23mil and two layers of 25mil fiberglass reinforced silicone rubber. Optional built-in high-limit thermostats designed to keep blanket below NEC article 500 T-Rating are available.

Silicone rubber heaters provide exceptional durability and longevity, plus moisture, chemical and radiation resistant. They are composed of heavy duty, extra thick silicone rubber which provides exceptional durability and longevity. Available with industrial strength pressure sensitive adhesive backing for easy installation and a patented grounded heating element for your safety meets NEC 427.23.

The resistance heating element is laminated between 4 layers of heavy duty fiberglass reinforced silicone rubber; two layers of 23mil and two layers of 25mil fiberglass reinforced silicone rubber. Optional built-in high-limit thermostats designed to keep blanket below NEC article 500 T-Rating are available.

METTLER TOLEDO's GPro 500 Series Tunable Diode Laser Gas Sensor

The use of Tunable Diode Laser (TDL) gas sensors is becoming more and more common in industrial processes. This is because they measure directly in the process gas stream without drift or cross-interference and are far more economical to purchase, install and maintain than other gas analyzer types. TDLs use a measurement technology called absorption spectroscopy: they output a beam of laser light at the same frequency that the gas to be measured absorbs light. The TDL analyzes the light after it has passed through the gas stream and calculates the quantity of the target gas in the stream.

Most TDLs are comprised of two parts: the laser source unit and a receiving/analyzing unit. These parts must be installed directly opposite each other, which is not always easy and misaligned can often occur. METTLER TOLEDO's GPro 500 Series solves this by combining both parts in a single unit. A probe attached to the GPro 500 sensor protrudes into the gas stream. A three-sided mirror at the end of the probe directs the beam back through the probe to the receiver, so alignment is always perfect.

The series is available with a wide range of different probes and adaptions that allow the GPro 500 to be placed wherever required in a process. These include:

- a probe with a filter to prevent dust ingress

- a wafer probe for narrow (2") pipes

- an extractive cell for use with sampling and conditioning systems

- a White cell for trace level detection

Using a modular design, the GPro 500 tunable diode laser gas analyzer allows you to select the process adaption that fits your application, and match it with the parameter that you need to measure. We offer sensors that measure a variety of gases including Carbon Dioxide (CO₂), Carbon Monoxide (CO), Hydrogen Chloride (HCl), Hydrogen Sulfide (H₂S), Moisture, Ammonia (NH₃), Methane (CH₄) and Oxygen (O₂).

The GPro 500 does not require maintenance-prone extractive and conditioning systems. This means that you receive consistent performance from your tunable diode laser gas analyzer without the downtime and cost associated with these traditional systems. You achieve reliable uptime, critical in safety applications, at a reduced cost of ownership.

For more information on METTLER TOLEDO Gas Analysis, contact Alliance Technical Sales.

630-321-9646

Innovative Solutions to Difficult Paper Mill Level Application

Magnetic Level Gauges and Magnetostrictive Level Transmitters for Black Liquor Chemi-Washer in Paper Mill

Black liquor is a waste product found in paper mills from the processes used to break pulp wood down into usable fibers. Many different methods are used to wash black liquor from the fibers before they are sent to the paper / cardboard making sections of the mill, one of which is a black liquor Chemi-Washer. The Chemi-Washer consists of a train of eight washes used to clean black liquor off of the paper fibers. The waste liquid gets progressively cleaner through each section of the train. DP transmitters are traditionally used to measure level in each section of the washer.

Black liquor is a waste product found in paper mills from the processes used to break pulp wood down into usable fibers. Many different methods are used to wash black liquor from the fibers before they are sent to the paper / cardboard making sections of the mill, one of which is a black liquor Chemi-Washer. The Chemi-Washer consists of a train of eight washes used to clean black liquor off of the paper fibers. The waste liquid gets progressively cleaner through each section of the train. DP transmitters are traditionally used to measure level in each section of the washer.Jogler, a leading manufacturer of industrial level instrumentation offers a case study on successfully handling this application.

Visit this page to download the full application case study.

Real-Time Bioburden Monitoring in Pharmaceutical Water with the Mettler Toledo 7000RMS

Have you ever experienced microbial contamination that led to an out-of-spec event, water system quarantine, or product recall even though you perform routine testing? How much time and cost did it take investigate or undo this damage? Even with false positive results, it’s often too late.

The water loop has to be sanitized, rinsed, retested and the affected product may be a total loss.

While plate counting is a regulatory requirement, there are inherent risks and delays that can greatly impact the accuracy of test results. Let’s take a look at these risks.

- No matter how careful you are, contamination can still occur at any stage of sampling.

- Waiting 5-7 days to get results causes you to use “at risk" water without knowing the microbiological quality.

- A sample you take now could yield very different results than a sample taken minutes or hours later.

- Sampling too infrequently can also cause you to miss an excursion.

- You can only count what will culture and colonies you can actually see.

- Such variables and limitations can mislead your assessment of the water quality.

The Mettler Toledo 7000RMS advanced laser-induced fluorescence technology provides a direct cell count of microorganisms present in pharma-grade waters. Overcoming limitations of growth-based laboratory methods that are an estimation of microbial presence and dependent on time and incubation conditions.

Counts microorganisms from as small as 0.50 microns and accepts direct input line temperatures of up to 90ºC. The Mettler Toledo 7000RMS delivers 24/7 monitoring of water treatment, storage tanks, distribution loops, points-of-use and clean-in-place processes.

Applications: Continuous monitoring of PW, WFI and UPW

- Distribution loops

- Sub loops

- Point-of-Use

- Return loops

- Recirculating storage tanks

- Grab samples

- Post purification before storage

- Sampling points

https://alliancets.com

(630) 321-9646

A Better Way to Measure Dissolved Oxygen in Power Plant Pure Water Systems

DO is measured at several locations in a water system. Traditionally, DO is measured with polarographic sensors, which use a gas permeable membrane to separate the sample from the electrochemical cell inside. Depending on the operating environment, polarographic sensors can require monthly electrolyte and membrane replacement. After service, the sensor cannot produce meaningful readings for several hours because of required polarization. They are also sensitive to sample flow rate and experience interference from dissolved hydrogen.

|

| Mettler Toledo pure water optical DO sensor |

The Mettler Toledo Thornton pure water optical DO sensor provides a fast, accurate and low-maintenance method of measuring dissolved oxygen concentration in power plant pure water systems.

For more information for any Mettler Toledo Process Analytics product, contact Alliance Technical Sales. Visit https://alliancets.com or call 630-321-9646.

New Jogler Magnetic Level Gauge, Magnetostrictive and Laser Level Transmitter Catalog Available

Jogler, a Baton Rouge, Louisiana manufacturer of high quality high quality magnetic level gauges, magnetostrictive transmitters, laser level transmitters and point level switches has a new 2019 product catalog available.

Level Monitoring & Controls

- Magnetic Level Gauges and Accessories

- Magnetostrictive Level Transmitters

- Laser Level Transmitters

- Direct-Reading Liquid Level Indicators

- Direct-Reading Liquid Flow Indicators

Tags:

control,

Illinois,

Indiana,

Iowa,

Jogler,

laser,

level,

Magnetic Level Gauges,

magnetostrictive,

Wisconsin

Superior Sales Representation, Commitment to Customers & Principals, Strategic Thinking & Planning

Established in 2000, Alliance Technical Sales, Inc. is a manufacturers’ representative agency providing numerous process control instrumentation solutions to customers across a wide range of industries.

Through the years we have specialized in providing in-line liquid analytical solutions and take great pride in the fact that Alliance Technical Sales is well known to customers throughout the Midwest, and highly respected in the instrumentation industry by the manufacturer’s we represent. By combining world-class products, application expertise, and unsurpassed customer service, Alliance Technical Sales enables its clients to increase manufacturing efficiency, reduce production costs, and improve product quality and value.

Alliance Technical Sales

https://alliancets.com

630-321-9646

It's Really Cold! Are Your Pipes, Tanks, Totes, and Valves Freeze Protected?

Winter is here in full force. Plant operators and plant maintenance must be vigilant in preventing the freezing of their equipment. Cold temperatures can often damage or destroy objects and their contents. Pipes, valves, tanks, vessels, conveyers, and housings are examples of common objects that can be hurt by the cold and have devastating consequences, costly downtime and unplanned outages.

Anticipating freezing conditions and protecting buildings, equipment, and grounds against freeze damage is a vital part of a Facility Maintenance Program. There's a wide range of freeze protection applications you need to consider, including pipe tracing, drum heating, roof and gutter de-icing, IBC heating, valve de-icing, vessel heating, and enclosure heating.

Ensure that whatever means of freeze protection you have available are ready. Failure to ensure these systems are properly protected from freezing can have catastrophic consequences. Act now, before it's too late.

Download a freeze protection checklist and freeze protection product catalog here.

Anticipating freezing conditions and protecting buildings, equipment, and grounds against freeze damage is a vital part of a Facility Maintenance Program. There's a wide range of freeze protection applications you need to consider, including pipe tracing, drum heating, roof and gutter de-icing, IBC heating, valve de-icing, vessel heating, and enclosure heating.

|

| Freeze Protection Products (BriskHeat) |

Download a freeze protection checklist and freeze protection product catalog here.

Keep Your Process Piping, Valves, and Instruments Insulated with the BriskHeat Silver-Series Insulators

The BriskHeat Silver-Series insulators are a configurable insulation system made of durable, high-temperature cloth that allows for very easy installation and removal. The Silver-Series provides 1” thick, needle-punched fiberglass insulation with hook & loop closures. The innovative design applies very efficient thermal insulation for hot or cold pipes, valves, instrumentation, tanks and vessels in industrial and commercial environments. Custom designs can be manufactured for unique requirements.

Alliance Technical Sales

https://alliancets.com

630-321-9646

Subscribe to:

Posts (Atom)