As the winter months approach, the need for freeze protection in commercial and industrial facilities grows increasingly urgent. Today's commercial and industrial complexes aren't just basic storage units or manufacturing hubs; they are sophisticated, multi-dimensional entities often housing intricate machinery, expensive equipment, and digital infrastructure. The broad exposure of these facilities to various risks, particularly when under-prepared for cold weather, can result in significant losses.

Every year, many facility managers postpone or overlook freeze protection measures, believing they have ample time or aren't critically necessary, a precarious misjudgment. Given the multifaceted nature of modern facilities, even a minor freeze event can cause a cascade of issues. Water pipes can burst, causing flooding; machinery can malfunction, leading to production halts; and electronic systems can fail, resulting in data losses.

Apart from the direct damages, the ripple effects of such events can be monumental. Disrupted operations can lead to missed deadlines, lost contracts, and a tarnished reputation in the marketplace. Furthermore, the financial implications of repairs, replacements, and potential legal claims can be staggering.

In today's fast-paced, highly interconnected commercial world, downtime is a luxury most businesses can't afford. It is not just about the immediate monetary losses but the long-term impact on brand trust and customer loyalty. Preventative measures, like early freeze protection, are cost-effective and essential for ensuring uninterrupted operations.

The importance of timely freeze protection in contemporary commercial and industrial facilities is not to be overstated. By addressing potential risks proactively, businesses can safeguard their operations, protect their assets, and maintain their standing in the competitive market landscape. It's a small investment with a profound payoff: ensuring the smooth continuity of operations, regardless of the weather.

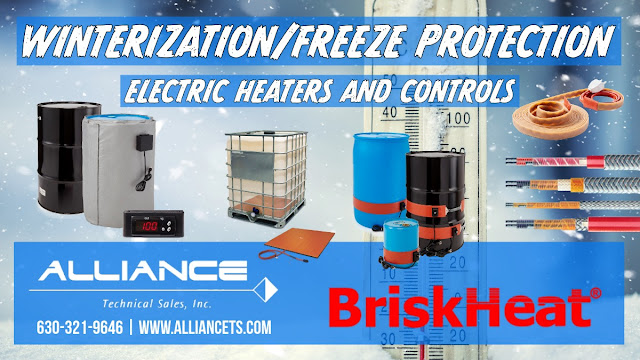

Established as a benchmark in the electric heating industry, BriskHeat has been dedicated to providing customers with top-tier heating solutions tailored to a myriad of applications. Recognized for their innovative approach, BriskHeat has developed a wide range of products designed to address the specific challenges posed by freezing temperatures.

BriskHeat's capabilities are not confined to a single product or application; they span a diverse spectrum of applications ranging from commercial to industrial needs. At the core of their product lineup are freeze protection solutions. These products are meticulously designed to prevent damage to equipment, machinery, and infrastructure during cold weather. They have consistently demonstrated their expertise in ensuring that businesses can operate seamlessly, regardless of how low the temperatures drop.

The BriskHeat product offering includes:

- Drum/Pail Heaters & Insulators

- Wraparound Tote Tank/IBC Heaters & Insulators

- Silicone Rubber Tote Tank/IBC Heater & Control

- Hazardous-Area Rated Silicone Rubber Drum Heater

- XtremeFLEX® Silicone Rubber Heating Tapes

- RKP XtremeFLEX® Silicone Rubber Heating Tapes

- XtremeFLEX® Silicone Rubber Heating Tapes

- Digital Temperature Controllers

- Outdoor Digital Controllers

- Ambient Sensing Capillary Temperature Controllers

- On/Off Thermostats

- Bulb & Capillary Temperature Controllers

- Hazardous-Area Equipment Bulb & Capillary Controllers

- Hazardous-Area Silicone Rubber Heating Blankets

- Heavy-Duty Silicone Rubber Heating Blankets

- Standard-Duty Silicone Rubber Heating Blankets

- Enclosure Heaters

- Crankcase Heaters for HVAC/R Compressors

- Mica Band & Nozzle Heaters

- Screw Plug Immersion Heaters

- Immersion Cartridge Heaters

To learn more about these products, visit this Alliance Technical Sales link and open the "2023 Electric Heating and Freeze Protection Solutions" link.

BriskHeat is a beacon of reliability and innovation in the electric heating world. Their commitment to excellence, especially in freeze protection products, positions them as a trusted partner for businesses aiming to combat the challenges of winter with confidence. For more information about BriskHeat products in Indiana, Illinois, Iowa, and Wisconsin, contact Alliance Technical Sales. Contact them at 630-321-9646 or visit their website at https://alliancets.com.